Opções adicionais

Opções adicionais

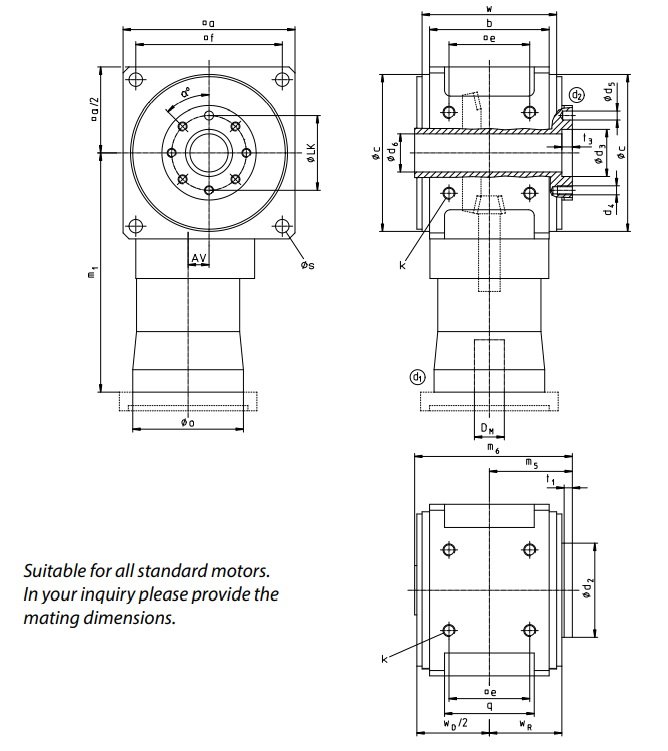

ESPECIFICAÇÕES TÉCNICAS

We would be glad to advise you

In many cases, multi-stage bevel gearboxes are recommended due to the energy footprint. Benefit from our experience in the manufacture of high-quality gears and gearboxes. Feel free to contact us with a description of your own specific drive scenario. We would be delighted to assist any way we can.

- Aluminium model: Lightweight construction is becoming increasingly important in today’s world. If the weight of a gearbox is crucial, our standard gearboxes can be ordered with aluminium housing components. This can save up to 40% on weight, depending on the size.

- Nickel-plated version: Nickel-plated housing surfaces are another option for surface finishing and corrosion protection.

- Reinforced bearings:

- To accommodate increased radial forces (e.g. belt drives);

- To accommodate increased axial forces (e.g. spindle drives);

- To increase the transmissible nominal torque at low rotational speeds.

We offer a solution for almost every application scenario in the field of drive technology. Contact us and describe your application scenario, and we will work with you to find the best solution for your specific application.

DOCUMENTAÇÃO TÉCNICA

Nenhuma informação disponível.

Nenhuma informação disponível.

DOCUMENTAÇÃO TÉCNICA

Aviso

Você pode solicitar no módulo abaixo um orçamento e também uma videoconferência.

ORÇAMENTO

Ficou interessado? Ligue:

11 4497-1735